The dryer suits all kind of solutions like emulsion and suspension.It also suits to thermal sensitive materials such as biologicals,biopesticide and enzymes.Activity of the material won't get affected when drying.

Ceramic powder is dried in the spray dryer within a very short time with satisfying final moisture.

|

Model

|

OLT-SD05L

|

|

Inlet air temperature control

|

30℃ ~ 300℃

|

|

Outlet air temperature control

|

30℃~ 140℃

|

|

Centrifugal nozzle

|

2000-40000 rev / min (adjustable)

|

|

Evaporation water volume

|

5000mL/H

|

|

Maximum feed amount

|

Up to 5000ml/h (adjustable)

|

|

Feeding mode

|

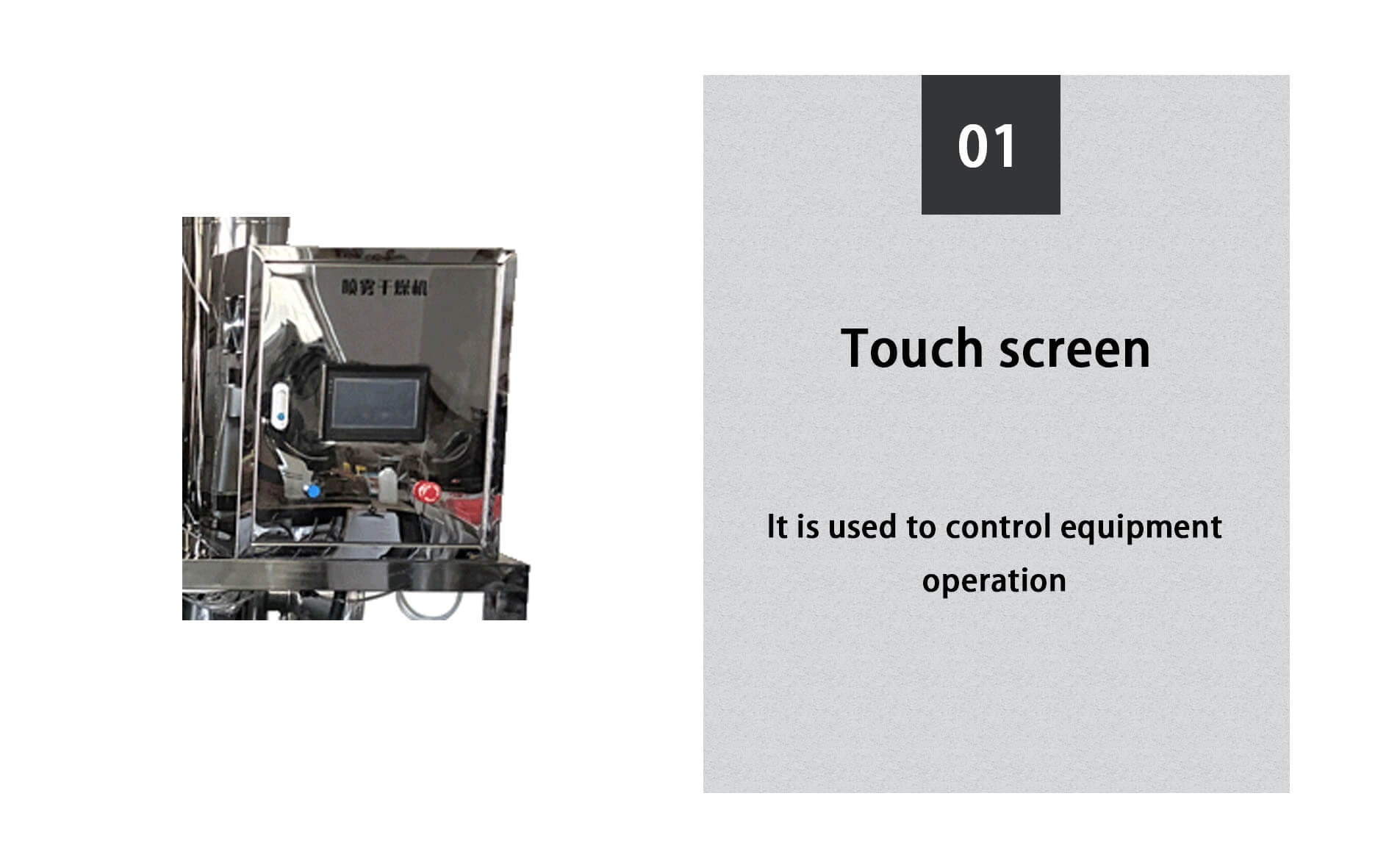

Peristaltic pump adjustment, using touch screen to adjust speed

|

|

Minimum feed amount

|

50mL

|

|

Temperature control accuracy

|

± 1 ° C

|

|

Average drying time

|

1.0~1.5S

|

|

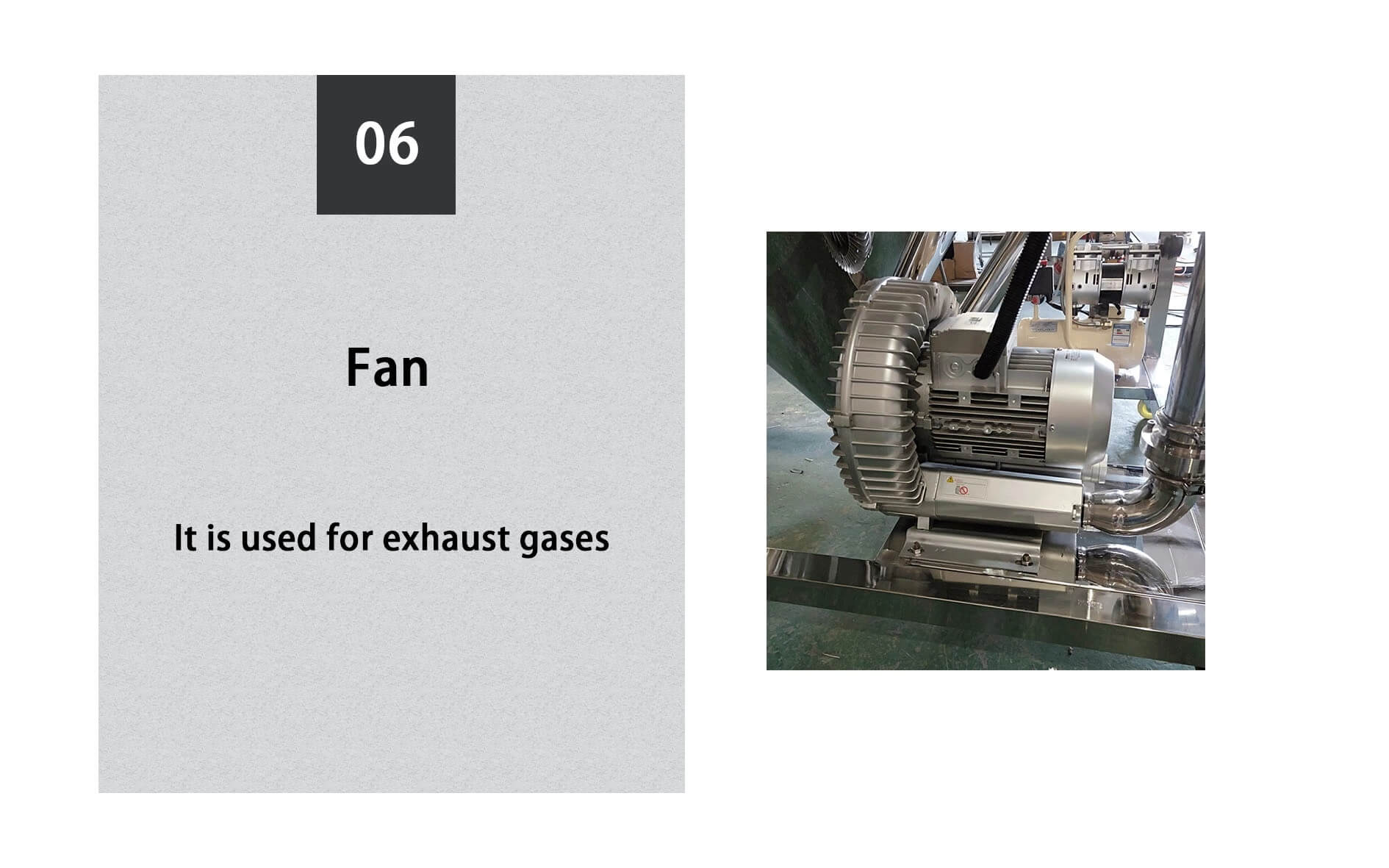

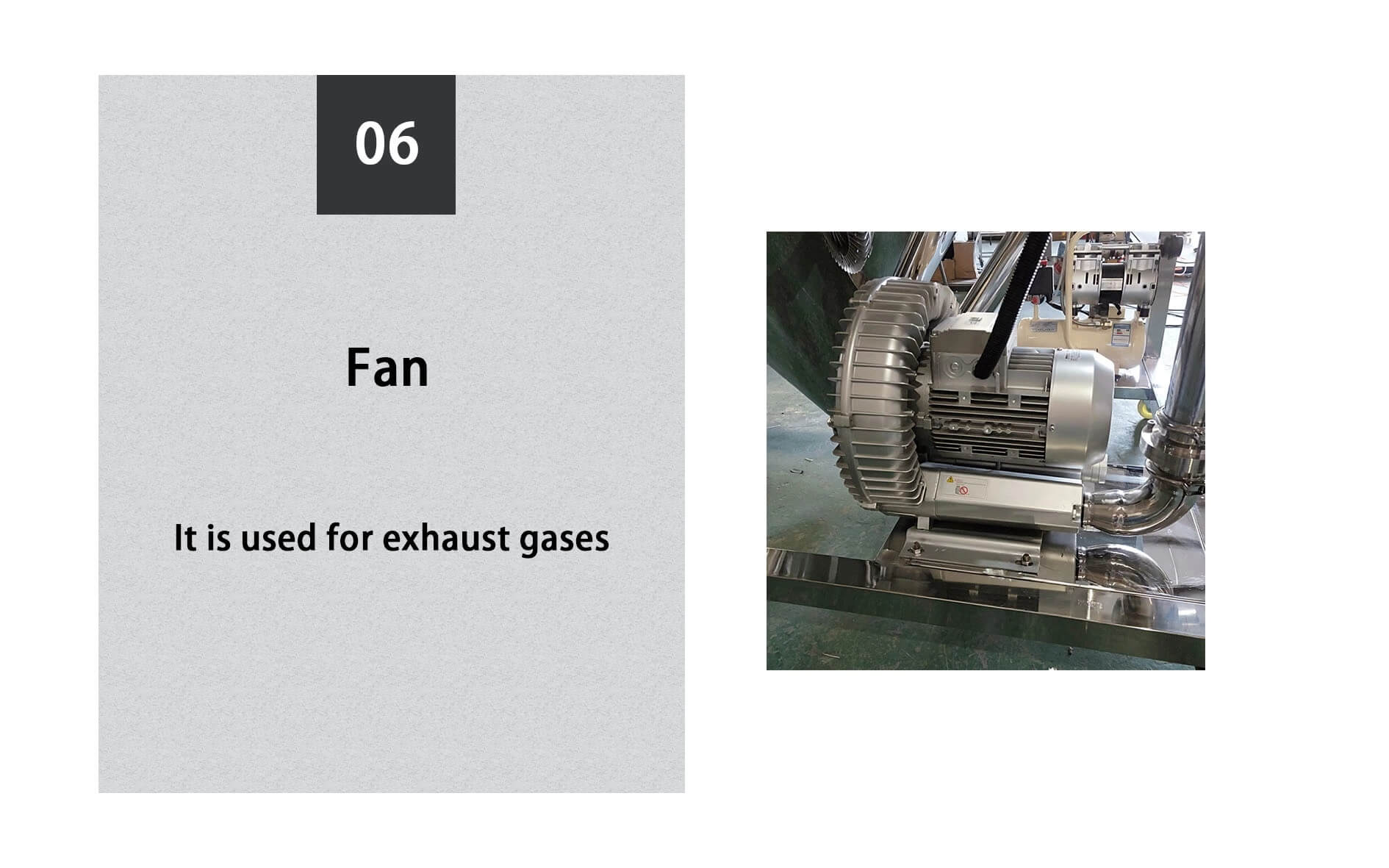

Fan

|

2.2KW Maximum air volume 315m3/min Maximum positive pressure: 40 (kpa) Maximum negative pressure: -32 (kpa) Speed: 2800 (r/min)

|

|

Machine power

|

9KW / 380V

|

|

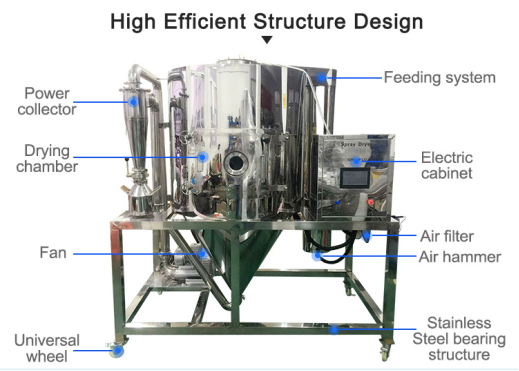

Double mirror stainless steel drying tower diameter

|

Inner diameter 1000mm outer diameter 1100mm height 2000mm

|

|

Equipment size

|

2000mm*1100mm*2200mm(L*W*H)

|

|

Packing size

|

2200mm*1350mm*2500mm(L*W*H)

|

|

Package weight

|

585kg

|

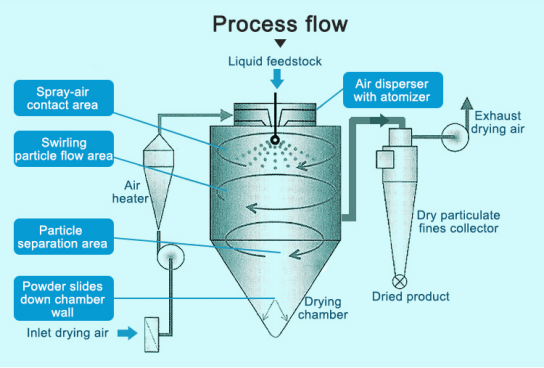

Working principle:

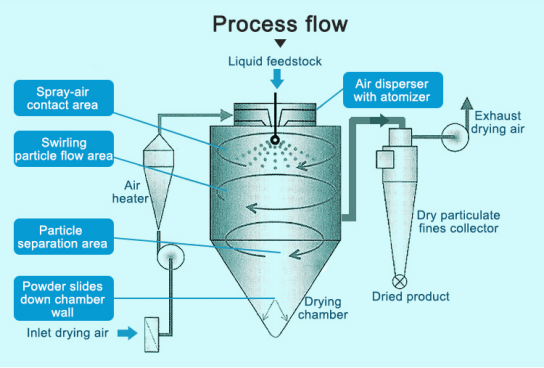

The working principle of the machine is that after the air passes through the filter and the heating device, the hot air distributor enters the top of the drying chamber, and the hot air passing through the hot air distributor uniformly enters the drying chamber and rotates in a spiral shape, and simultaneously sends the liquid to the device. At the centrifugal spray head at the top of the drying chamber, the liquid is sprayed into a performance mist droplet, so that the surface area in contact with the hot liquid and the hot air is greatly increased, the moisture is quickly evaporated, and the finished product is dried in a very short time. The coarser product is recovered from the collection drum at the bottom of the dryer and the exhaust gas is discharged by the centrifugal fan.

Air through filtering and heating, enter the hot air distributor which is at the top of spray dryer, hot air spiraling evenly into the drying chamber. Liquid through the high-speed centrifugal automizer which is at the top of drying chamber, (rotating) centrifugal spray into tiny fog droplet, then contact with the hot air flow, drying finish product in a very short time and whereabouts. Finished product output continuously between the drying tower bottom and cyclone separator, exhaust through dust catcher emptying by induced draft fan.

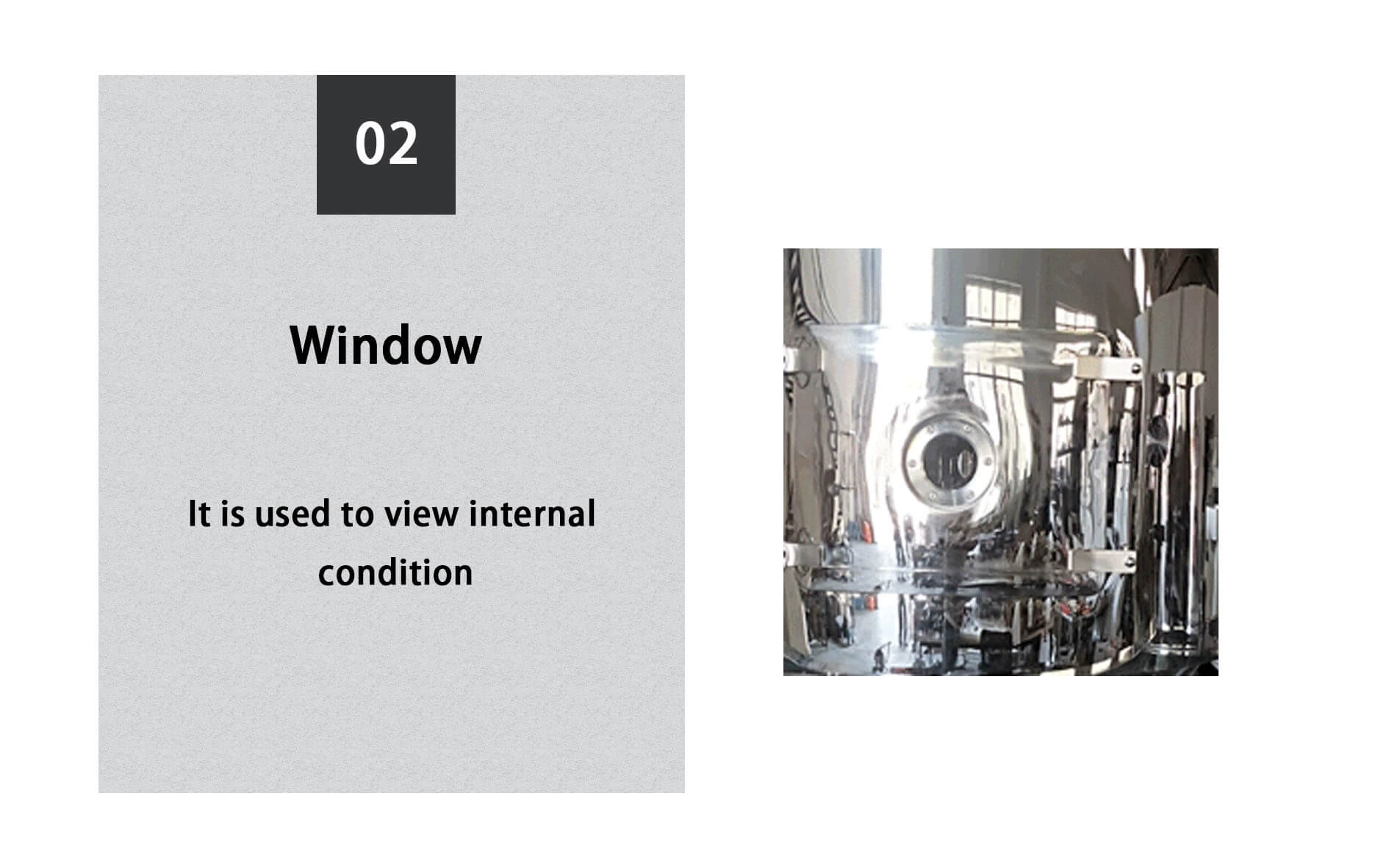

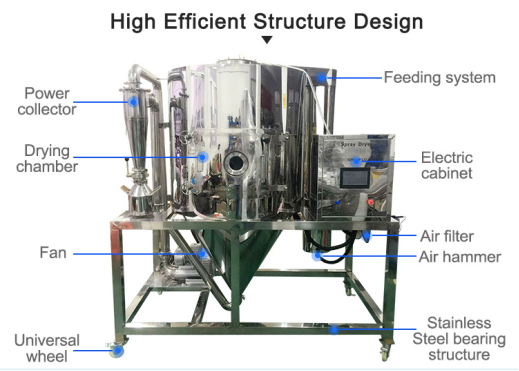

Detail Images