- Home

-

-

-

- Software para potenciostato

- Video tutorial Potenciostato Admiral

- Potenciostato Squidstat Solo ±100 mA ±10V

- Potenciostato Squidstat Prime 4 canais ±250 mA ±10V

- Potenciostato Squidstat Plus ±1A EIS 2MHz ±10V

- Potenciostato Squidstat Penta ±5A EIS 1MHz ±10V

- Potenciostato Squidstat Decka ±10A EIS 1MHz ±10V

- Potenciostato Squidstat Venta ±20A EIS 1MHz ±6V

- Potenciostato Zenniun XC ±2A ±14V

- Potenciostato Zenniun Pro ±3A ±15V

- Potenciostato Zenniun X ±4A ±15V

- Células voltamétricas

- Sensores BVT

- Eletrodos para Tituladores e cabos

- Cabos e conectores

-

-

- Detector de condutividade sem contato C4D

- Analisador de Impedância ( EIS )

- Ciência da Separação

- Medidores Isopods ( pH & ISE, dO2 )

- Sistema de aquisição de dados e-corder

- SDx Tethered Membrane Systems

- Sistema para aquisição de dados para cromatógrafo

- Eletrodos, transdutores e acessórios

- Softwares

- Kits e pacotes de ofertas especiais

- Microbalança de cristal de quartzo

- Espectroeletroquimica

- Neuroeletroquímica

-

- Potencisoatto para teste em baterias

- Software para potenciostato

-

-

- Liquefator de Hélio

- Nitrogênio gasoso

- Oxigênio Líquido

- Convertedora de Nitrogênio em alta pressão ( LN2 é convertido em GN2 de alta pureza a pressões superiores a 5.000 psi e a 70 ° F )

- Linhas de transferência NItrogênio Líquido e Válvulas solenoides criogênicas

- Compressor de ar isento de óleo scroll

-

- Câmaras de teste de umidade e temperatura

- Câmaras de teste de temperatura da bateria

- Câmaras de teste de mudança rápida de temperatura

- Câmaras de teste de choque térmico

- Câmaras de Teste de Intemperismo

- Porta de detecção de metais para medição de temperatura

- Sistema de medição de vídeo e visão

- Teste de máscara (N95, KN95, máscara descartável)

- Forno de calibração

- Teste de choque

- Teste de gotas

- Biofermentadores e Bioreatores

- Microscopia Eletrônica

- Analisaodr de óleo em água

- Leitor de microplacas e Espectrofotômetro

- Central de Inclusão em Parafina

- Graxas e fluidos

- Bomba de alta pressão

- Valvulas automaticas de alta pressão

- Bomba para cromatografia

- Transdutor Camille Bauer

- Geladeira, Refrigerador e Freezer RFID

- Nace

- Liquefator de hidrogênio

- Cannabis

- Oleo e Gás

- Automação e Sistema Industrial e Laboratorial

- Permeabilidade

- Instrumentação Analitica de Processo

- LCMS

- Recuperadora de CO2

- Tomografia por impedância

- NIR

- Bombas criogênicas

- Hidrogênio

- Sumitomo

- FreezeDryer

- Hélio

- Testes de permeabilidade

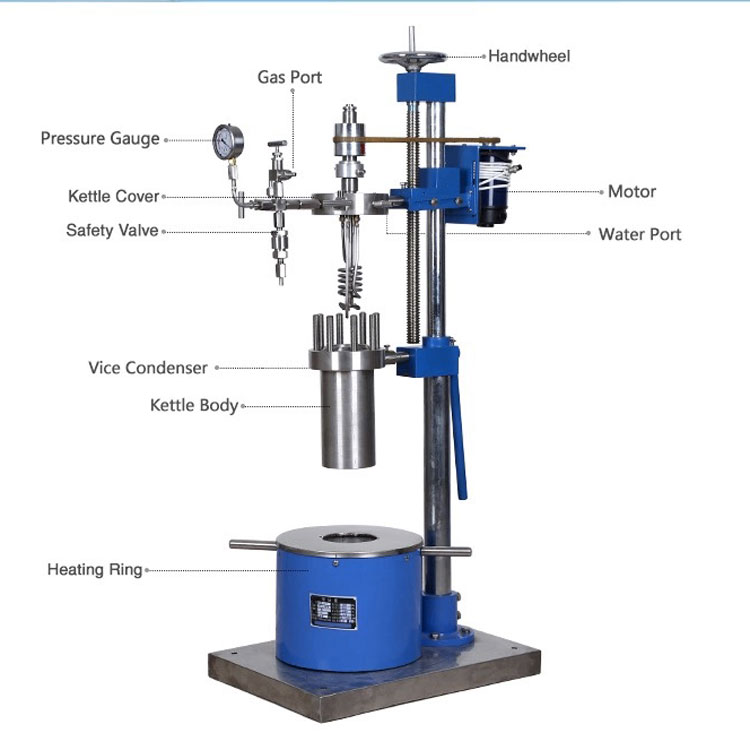

- Reator de Alta Pressão

- Spray Dryer

- Energia Renovável

- FitInstruments

- Datacenter

- Cilindro amostragem gas

- Analisador de Metanol

- FotoCatálise

- Analisador de mercúrio

- Camara de teste Ozonio

- Sensor de H2S

- Sensor de H2S

- Energia Fovoltaica

- Impressora 3D a laser

- Célula Combustível

-

-

- Ciência Adsorção

- Projeto Biogás H2

- Síntese de gás de CO2

- Relatório de teste de cannabis

- Bateria de Litio x Celula de H2

- Base de conhecimento NIR

- Referências em EIT

- Processamento de óleo de CBD

- Teste de permeabilidade

- FAQ eletroquímmica

- Catálogos eletrodo de referência

- Catalogos eletrodos de trabalho

- PSA x membrana

- Vídeos eletrquímica

- Soluções de Teste para Baterias de Nova Energia

- Cãmaras de teste para industria automotiva

- Processo de produção de CBD

- Remoção de clorofila de extrato de cannbis

- Viabilidade econômica extração CO2 supercrítico

- NMR Cooling

- Por que extratos de CO₂ Supercrítico?

- Gerador de Nitrogênio Liquido: Tecnologias

- Biopharmaceutical Industry

- Análise de custos Liquefator de Nitrogênio

-

- Pré Requisitos de instalação

- Carta de Exclusividade

- Termo de Garantia - Labsolutions

- Política de Compliance

- Código de Ética e Conduta

- POLÍTICA DE PRIVACIDADE E PROTEÇÃO DE DADOS

- Política de Relacionamento com Fornecedores

- Procedimento de Gestão de Riscos

- Plano Estratégico 2024-2026 Labsolutions

- Código de Conduta e Programa de Compliance

- Jobs in electrochemistry

- Blog Noticias Criogênicas

- Portfolio geral de produtos