Micro reactor is suitable for petroleum, chemical, chemical, pharmaceutical, polymer synthesis, metallurgy and other fields. For example, catalytic reaction, polymerization, supercritical reaction, high temperature synthesis, hydrogenation reaction, etc..

|

Model

|

OLT-HP-25ml

|

OLT-HP-50ml

|

OLT-HP-100ml

|

OLT-HP-250ml

|

OLT-HP-500ml

|

OLT-HP-1000ml

|

OLT-HP-2000ml

|

|

volume(ml)

|

25

|

50

|

100

|

250

|

500

|

1000

|

2000

|

|

Service temperature(℃)

|

RT-350℃,Higher temperatures can be customized according to customer requirements

|

|

Use pressure(Mpa)

|

-0.1-10 Standard10Mpa,Can be customized according to customer requirements

|

|

heating power(w)

|

600

|

1000

|

1500

|

1500

|

1500

|

1500

|

1500

|

|

control mode

|

1、PID artificial intelligence adjustment, LCD 2, program temperature control

|

|

Mixing form

|

Magnetic stirring

|

|

Mixing power(w)

|

80

|

|

Stirring speed(rpm)

|

0-1500

|

|

Positive and reverse regulation

|

Positive inversion

|

|

Temperature setting

|

Self setting function of temperature

|

Standard Configurations

| Serial number |

Name |

Number |

Company |

Remarks |

| 1 |

Chassis control display panel |

1 |

set |

HTLAB |

| 2 |

Finishing vessel |

1 |

set |

316L |

| 3 |

Wika pressure gauge 0-16mpa |

1 |

branch |

Germany |

| 4 |

Bursting disc unit |

1 |

slice |

C276 |

| 5 |

Thermocouple and extension wire |

1 |

root |

OMEGA |

| 6 |

Intake valve |

1 |

individual |

|

| 7 |

Intake valve |

1 |

individual |

|

| 8 |

Thermocouple sleeve |

1 |

root |

316L |

| 9 |

Bottom pipe |

1 |

root |

316L |

| 10 |

Graphite metal winding pad |

1 |

individual |

|

| 11 |

PTFE lining |

1 |

individual |

Matching |

| 12 |

Quartz glass lining |

1 |

individual |

Matching |

| 13 |

High-temperature magnet |

2 |

individual |

|

| 14 |

Torque wrench |

1 |

slice |

|

| 15 |

Fuse |

2 |

branch |

|

| 16 |

Instruction manual, certificate of approval, warranty card, packing list |

1 copies each |

share |

|

|

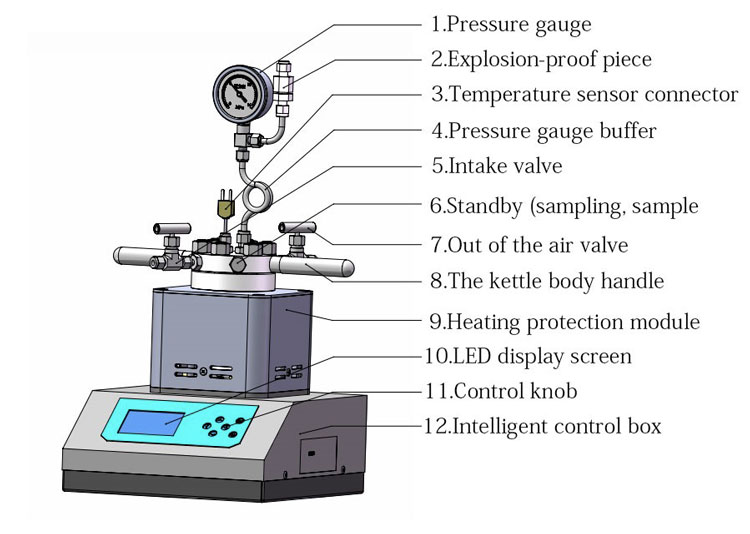

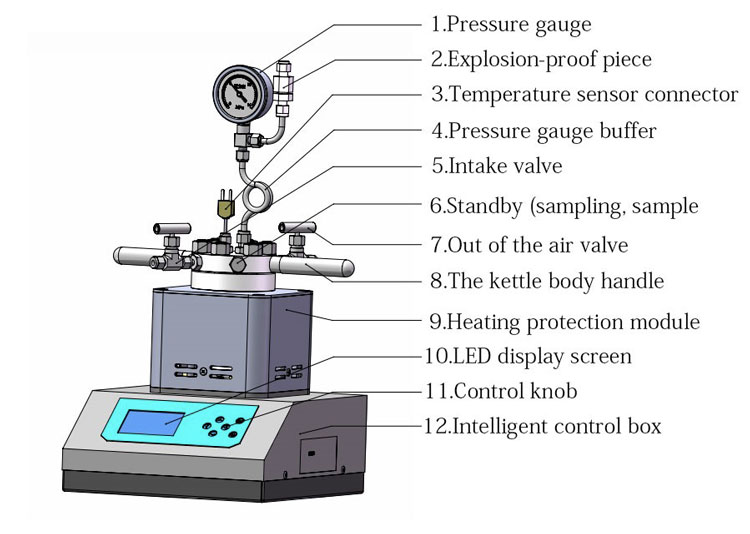

1, temperature warning function, over temperature alarm, self power-off protection.

1, temperature warning function, over temperature alarm, self power-off protection.

2 、 input adopts digital correction system, built-in thermocouple and thermal resistance non-linear correction form, accurate and stable measurement

3, the use of advanced artificial intelligence adjustment algorithm, without overshoot, with self-tuning (AT) function

4, timing function: can be under different conditions for 1-9999 minutes between the timing control;

5, positive reversal: can control the mixing motor, forward and reverse alternately rotating mixing;

6, digital display function: speed, temperature and time are digital display.

The accessories: intake valve, exhaust valve, liquid sampling valve, dip tube, pressure gauge, temperature sensor, explosion-proof membrane, high temperature magnetic etc.