Scheme One: Monitor by wireless digital display liquid level meter

Wireless digital display liquid level meter for low temperature gas cylinders belongs to mass liquid level meter, which is a measuring instrument for low temperature medium researched and developed by our company. It can measure and display the mass of the low temperature medium in the gas cylinder directly, accurately in real time. (It can also display mass percent). The measuring result will not be influenced by different medium components and changing temperature. It has advantages of high measuring precision, convenient installation and no wiring. It has been widely promoted in the industry market.

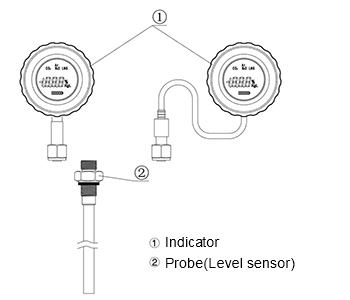

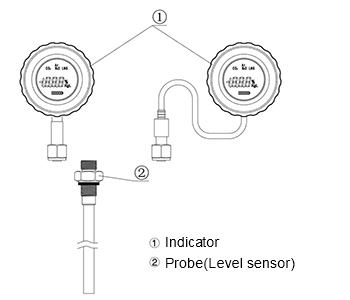

The liquid level meter is composed of mass sensor, digital display indicator (mass percentage indicator) and other components. See diagram below.

(Click the product picture to view the product introduction)

wireless digital display liquid level meter MT3/4/5

(Capacitance digital display, solid and durable sensor)

Typical application cases:

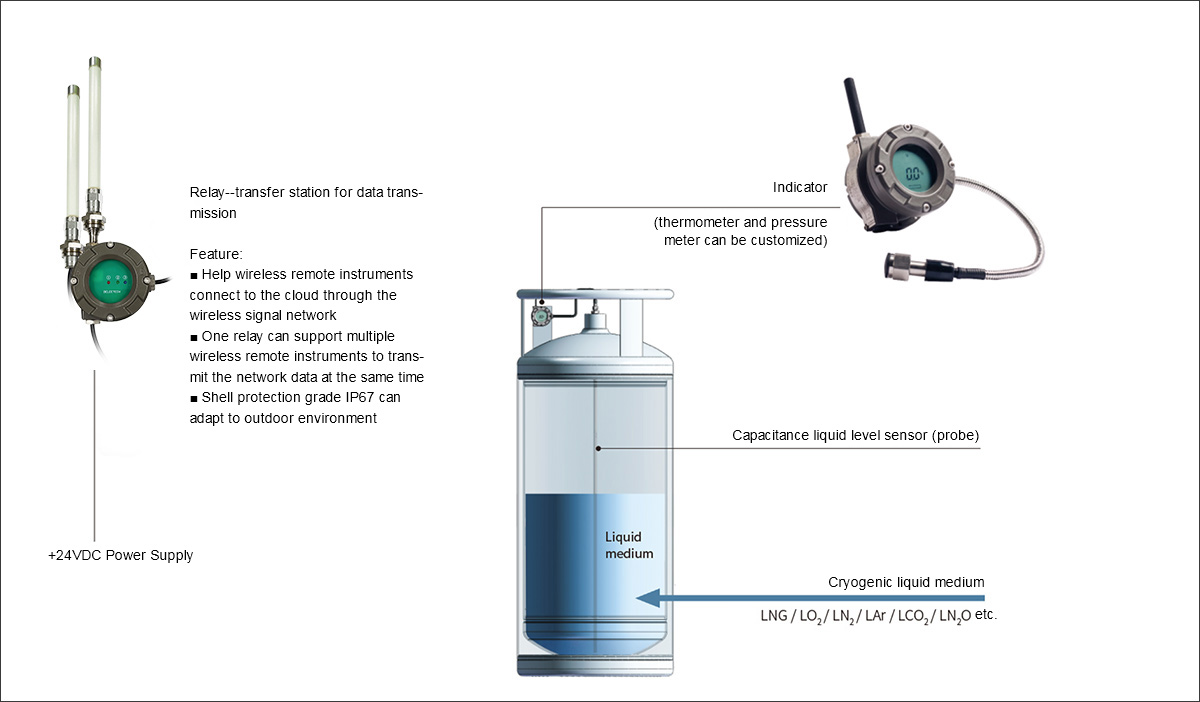

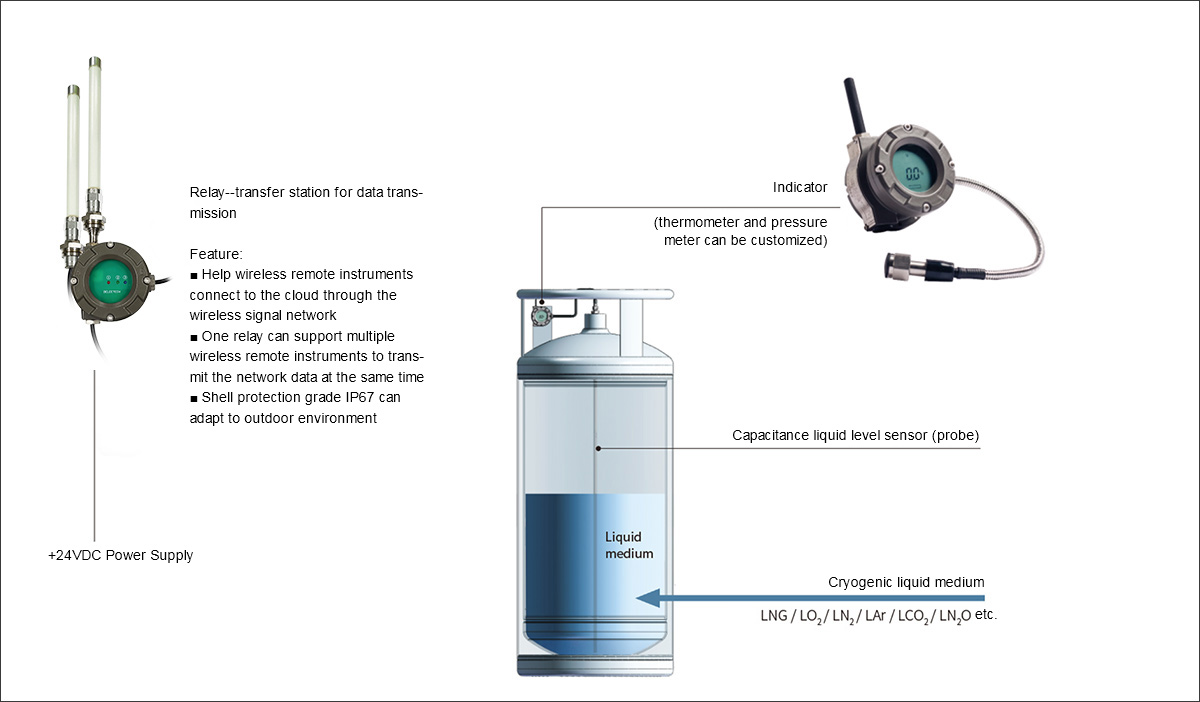

Scheme Two: Liquid level gauge monitoring through IoT

DeleeTech focuses on R&D and manufacturing of measurement sensors, making IoT instruments applied in many industries, and providing solutions for industrial upgrading of intelligent equipment. IoT instruments can monitor assets through computer and mobile phone synchronously. Users can gather information such as liquid level, pressure, location and temperature of the tank container on real time and set alert value on their own to realize real-time alert. Thus, achieve effective monitoring of the tank container, cost reduction, safety improvement and productivity promotion.

Multiple wireless remote liquid level gauges can be connected wirelessly through a relay.

(Click the product picture to view the product introduction)

Wireless remote transmission level gauge (MTM4)

Liquid level + pressure (optional), digital display networking

Wireless remote monitoring scheme for Dewar:

Features:

■ The Dewar is wirelessly connected to the network, with no wiring and less construction;

■ Liquid level and pressure (optional) can be monitored and alarmed in time, which can also be monitored by mobile App, computer Web terminal .

■ It can realize the remote on-line diagnosis and management of the instruments on the computer, including the operation of multiple medium measurement and conversion, which is easy to operate.

■ Low power consumption design of the battery: the service time of the battery is 3-5 years.

■ Large LCD can display mass percentage and weight which is convenient.

■ LCD Wide Temperature Range Design. Shell protection class: IP67

■ Ex i explosion-proof design with explosion-proof shell

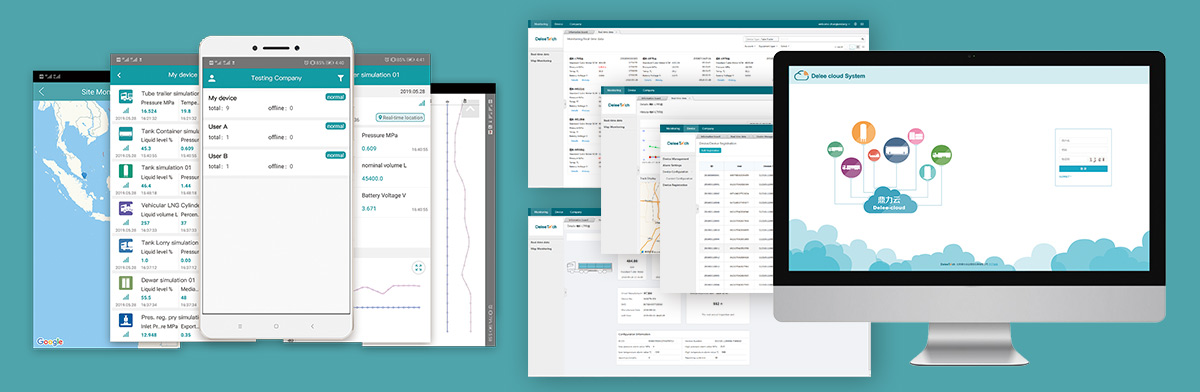

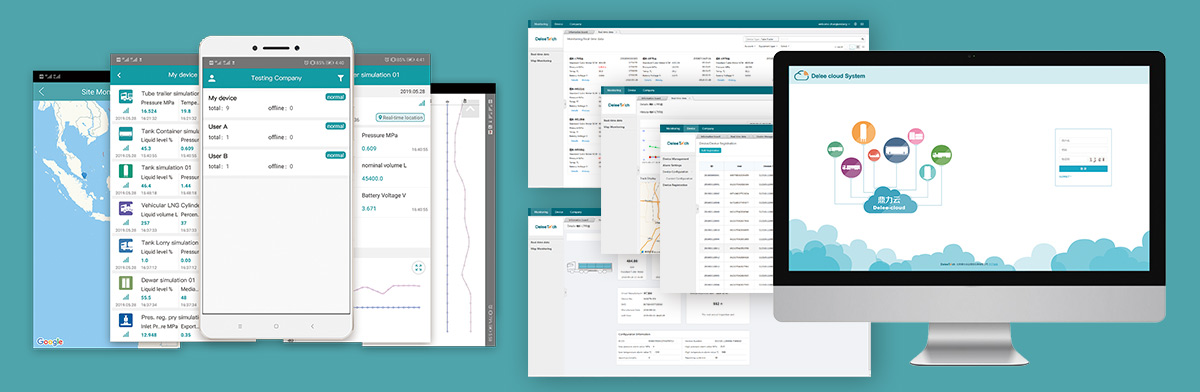

Cloud Platform Intelligence Control System:

Features of Mobile APP Client:

■ To view the information of liquid level, pressure, temperature, location, consumption rate and available time of tanks, liquid tankers, tank containers, cylinders, tube trailers, vehicular LNG cylinders, etc.

■ To view the temperature and pressure of the pipelines, such as gasification, pressure adjustment and so on

■ To view the instantaneous flow rate and accumulative flow of the flowmeter

■ Real time push and reminding of liquid level, pressure, temperature, battery voltage alert information

■ Shows the distribution of all the equipment belong to the company and the real time site location in the map

■ Historical data query, changes in level, pressure, temperature, gas consumption and so on over the past period of time

■ Charging statistics, reflect charging quantities, time points and other information in a period.

Features of PC end software:

■ To view the information of liquid level, pressure, temperature, location, consumption rate and available time of tanks, liquid tankers, tank containers, cylinders, tube trailers, vehicular LNG cylinders, etc., sheet and chart dual-mode display, more intuitive monitoring

■ Shows the distribution of all the equipment and sites belong to the company in the map

■ To view the temperature and pressure of the pipelines, such as gasification, pressure adjustment and so on

■ To view the instantaneous flow rate and accumulative flow of the flowmeter

■ User management: adding, modifying user unit information and authority, assign sites to users

■ Site management: view site name, IMEI number and detail information, add, modify the site name, display site location in the map;

■ Device management: view the detailed parameters of the device, edit and modify device detail information,set liquid level, pressure, temperature, battery voltage alert thresholds, alert clearly and push alert information to mobile APP client.

■ System query: provide changes of device liquid level, pressure, temperature over a past period of time, can be analyzed in data or curve chart, support export data in XLS format, provide the movement track of the device in a certain period of time, provide data query and comparison between two devices, convenient to compare the data from devices produced by different manufacturers.

Typical application cases: