Micro reactor has been widely used in chemical, chemical, pharmaceutical, polymer, metallurgy and environmental protection.Such as catalytic hydrogenation, polymerization, hydrometallurgy, esterification, spices synthesis, supercritical reaction.

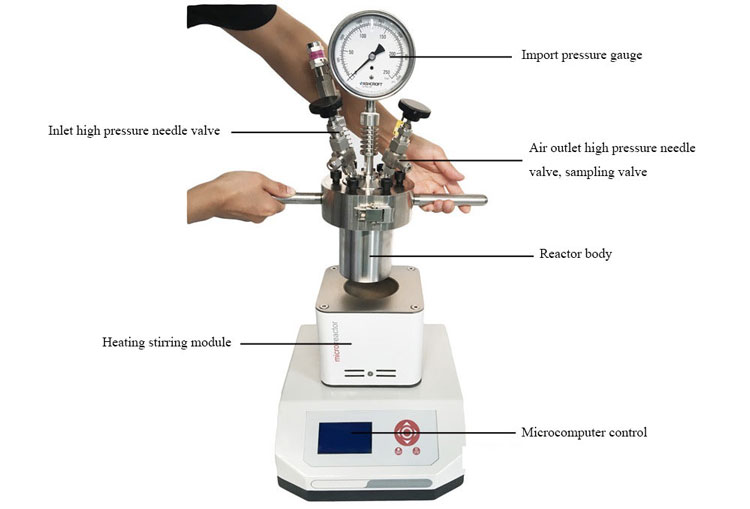

1.Appearance: the chassis shape adopts mold integration molding, the surface electrostatic spraying plastics is not only beautiful and generous and anti-corrosion and anti-static, but also makes the first line of defense for our safety experiment.

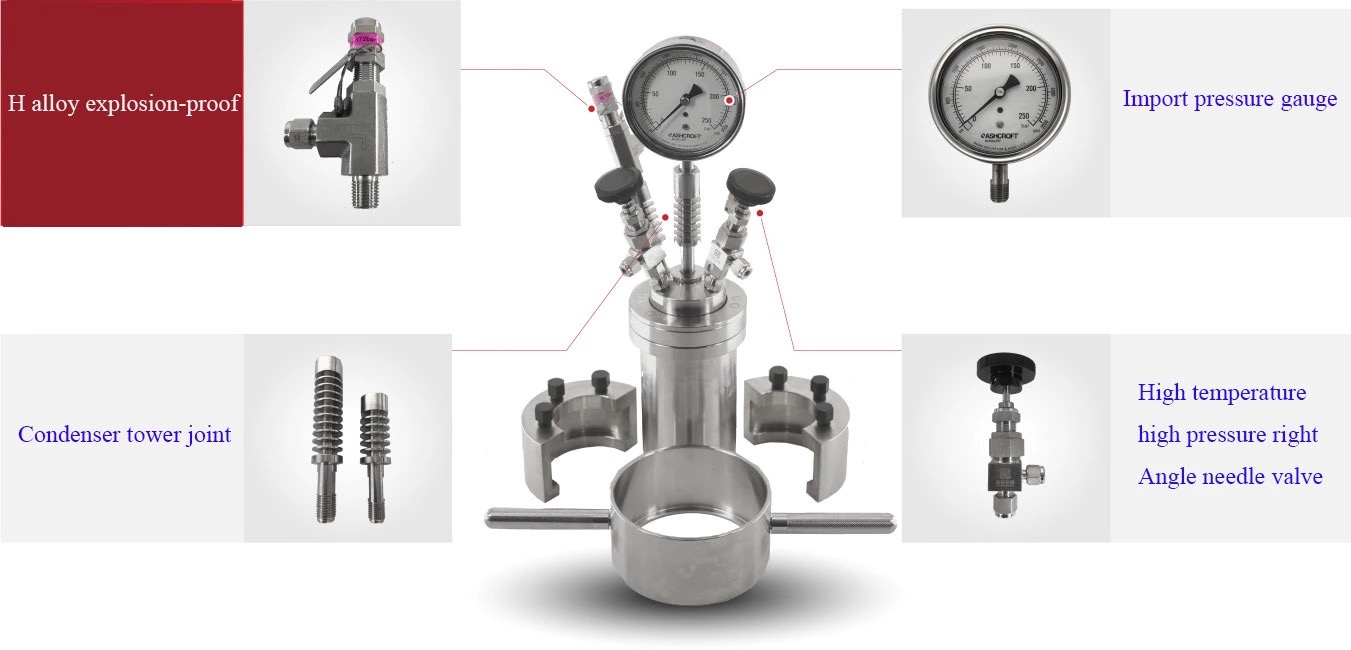

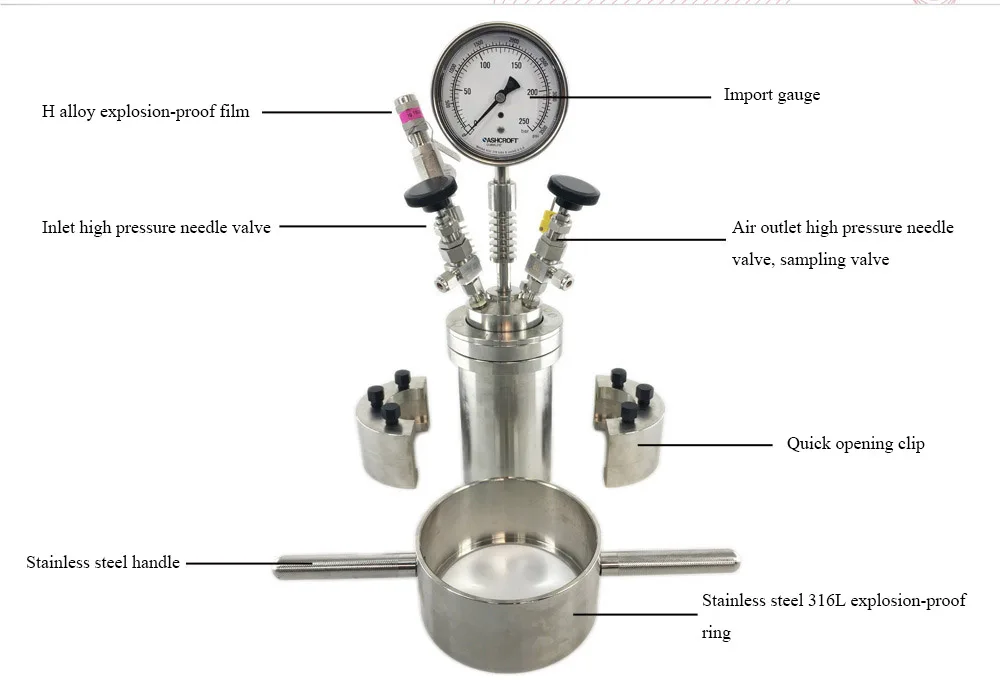

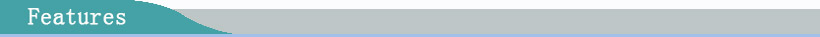

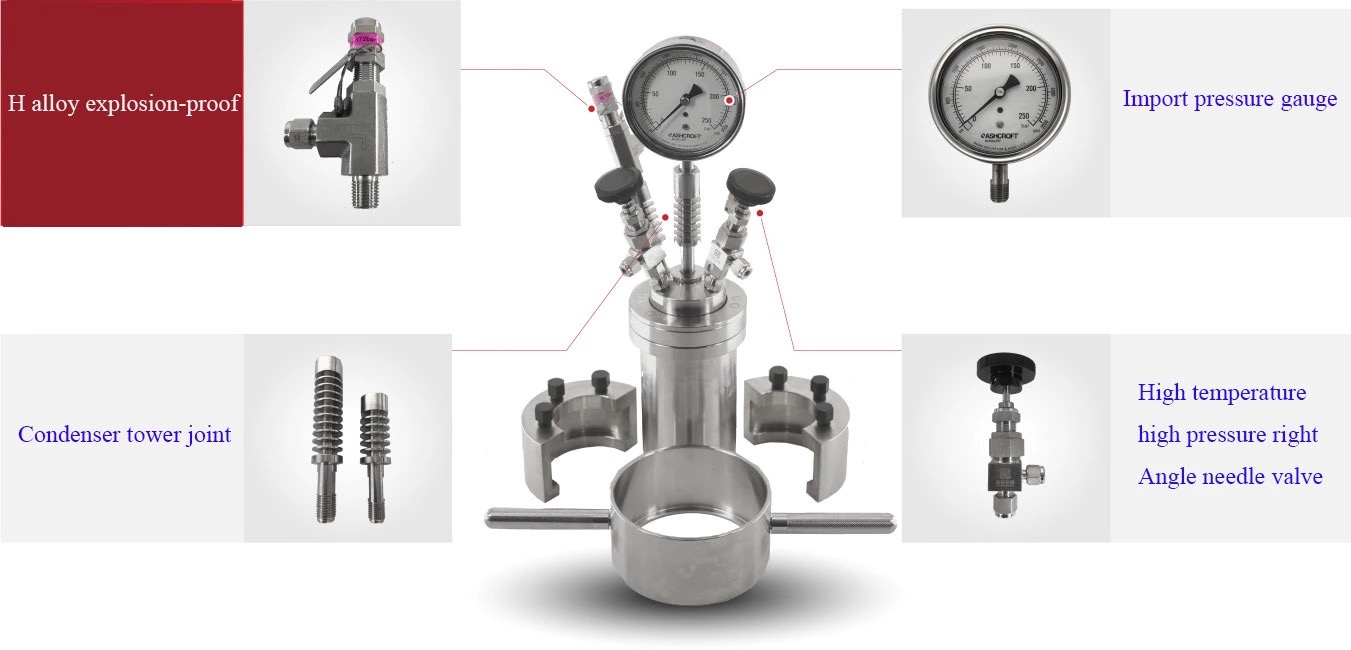

2.High quality imported accessories: original German wika radial pressure gauge, American omega k temperature sensor, harth alloy explosion-proof film and other high-quality imported accessories make a second line of defense for our safety experiment;

3.Patent type heating module: embedded stainless steel heating module is the first heating mode applied in micro counter, heating efficiency is the common aluminum heating, heating furnace heating, electric heating set of 1.5-2 times, life to three times higher than common modules and strong and beautiful deformation more on different parts of the residue for reaction kettle heating efficiency and the escort service life;

4.Complete material selection: standard quality T316SS stainless steel (316), also loyal 400 (monel 400), loyal 600 (Alloy600), Alloy C276 (harth Alloy C276), Alloy b-3 (harth Alloy b-3), Titanium (Titanium) and other quality metals are available;

5.Precise intelligent Controller: the mr-controller is specially designed for micro-reactor series.

(1)Accurate temperature control: the precision can reach 1 effective digit after the decimal point;

(2)Support self-setting function: temperature self-setting can be carried out according to different operating temperatures;

(3)Timing function: you can control the timing between 1-9999 minutes according to different conditions of use;

(4)Positive and negative rotation: the motor can be controlled to alternately rotate and stir forward and reverse;

(5)Digital display function: the speed, temperature and time can be digital display.

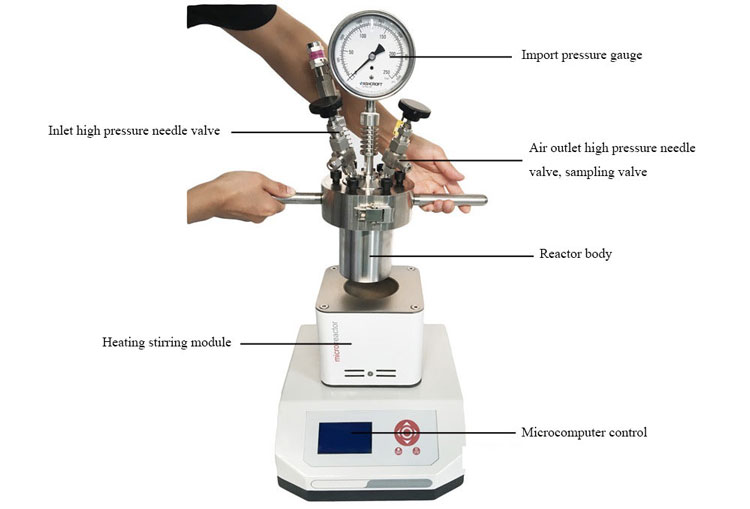

6.Complete standard configuration: gas injection valve, gas release valve, liquid sampling valve, probe bottom tube, pressure gauge, temperature sensor, explosion-proof film, high-temperature magneton, this configuration can meet the response requirements of most chemical processes.

Configuration list:

|

No.

|

Name

|

Quantity

|

Note

|

|

1

|

Heating Stirring Control Base

|

1

|

MR - Controller

|

|

2

|

Flange Body

|

1

|

316 L

|

|

3

|

Imported Wika Pressure Gauge (0-16mpa)

|

1

|

Germany

|

|

4

|

Explosion-Proof Film (Haversian Alloy),12.5mpa

|

1

|

C276

|

|

5

|

Gas Sampling Valve

|

1

|

|

|

6

|

Gas Release Valve

|

1

|

|

|

7

|

Omega Thermocouple For Temperature Measurement

|

1

|

United States

|

|

8

|

Extension Cord Of Thermocouple

|

1

|

United States

|

|

9

|

Thermocouple Sleeves

|

1

|

316 L Material

|

|

10

|

Dip Tube

|

1

|

316 L Material

|

|

11

|

Inlet Plate Sealing Ring

|

1

|

United States

|

|

12

|

Teflon Lining

|

1

|

Four Fluorine

|

|

13

|

Quartz Glass Lining

|

1

|

Quartz

|

|

14

|

Magneton

|

2

|

|

|

15

|

Special Tool Wrench

|

1

|

|

|

16

|

Fuse

|

2

|

|

|

17

|

Instruction Manual, Certificate, Warranty Card, Packing List

|

1

|

|